For HAPPY Visual Inspection

Making everyone involved in visual inspection happy

We contribute to manufacturing that is friendly to both people and the global environment.

Creating a Technician's Paradise

We pursue the question, "Why doesn't automation of visual inspection work?

OVIT POLICY

Facing Customers and Enjoying Our Work Together

Pursuing the Essence of the Essence of the Essence of the Essence of the Essence of the Essence of the Essence of the Essence

Set goals and move forward quickly and steadily

Self-improvement and problem-solving skills

Be curious, try new things.

HOW TO DO OVIT

Customer-first consulting

We make the best proposals for our customers. We will honestly tell them what we cannot do or what themes we would prefer not to do. This is because image processing inspections are not absolute, and there are things that people are happier doing than automating them.

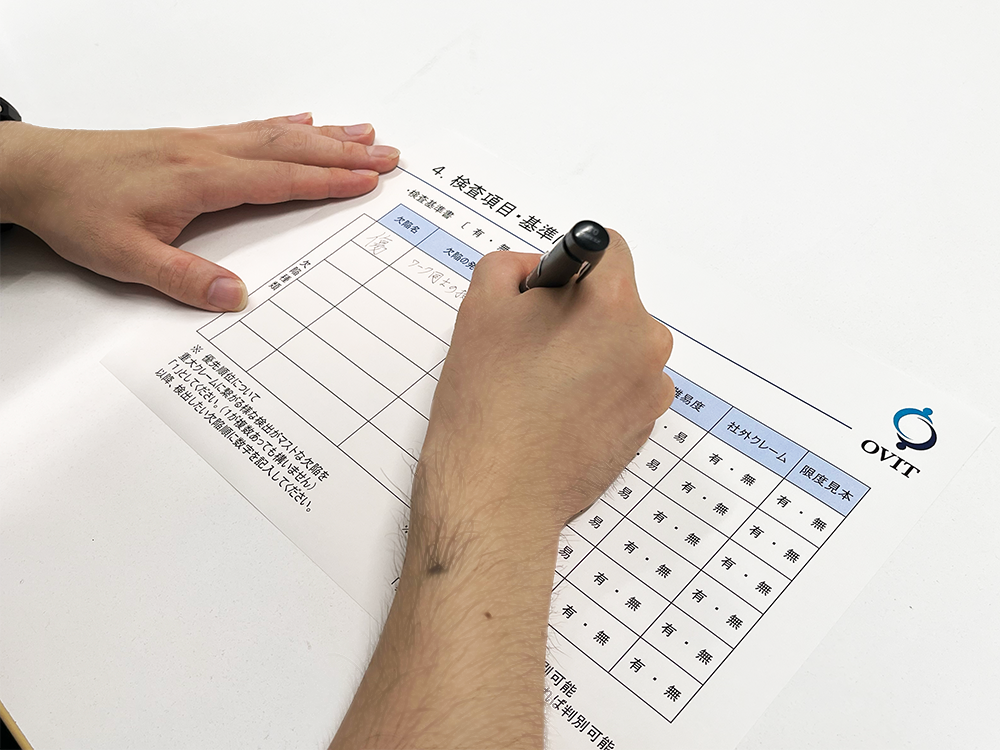

Users are responsible for setting up and operating the system.

Only the user, not the manufacturer or trading company, can determine quality.

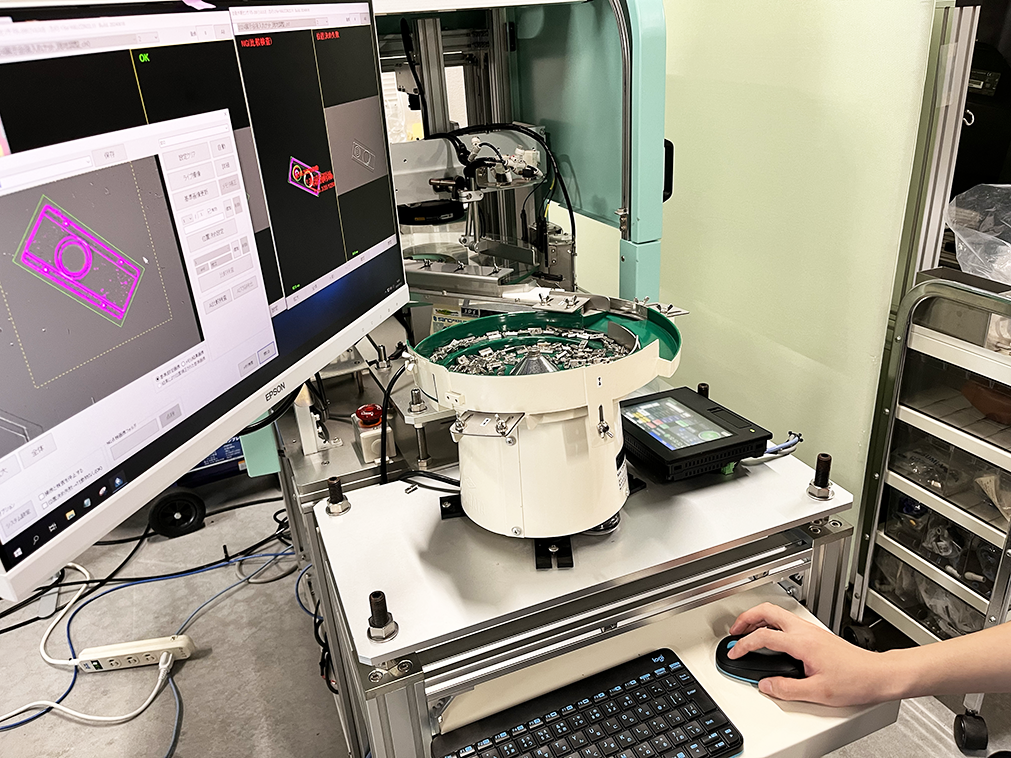

Inspection equipment made by an imaging shop

Some visual inspection devices are made by mechanical engineers, but optical conditions and operational aspects are not always considered. In this respect, the inspection systems we make take optical conditions and ease of maintenance into consideration.

Representative Message

Hirokazu Yamada

representative director (i.e. someone chosen by the board of directors from among the directors to actually represent the company)

Making everyone involved in visual inspection happy

I love automated visual inspection systems. When I see a "non-good product" that has been discharged by the FlexInspector running at a customer's site, I say to myself, "Wow, they can even take this kind of thing. That's amazing! I love being impressed by the results. Because it is a visual inspection system, we can see the results clearly and visibly.

Do you like automatic visual inspection equipment?

Don't you hate to look at them, being driven around by the settings day after day?

Do you think they are unreliable?

Are you worried that no one appreciates your hard work?

Many of the automatic visual inspection systems I know of... are hard to see and hear.

If you think about it calmly, you can see if it is possible to "detect 100% of all defects on every object using image processing.

That approach always leads to sad results.

I know the answer to automated visual inspection. I have seen many pleasant results. I also have a clear understanding of the homework that remains to be done. As someone who has escaped the labyrinth one step ahead of me, I am determined to open up the next world.

Company History

| 1999年 | Founded ovitin Nishikyo-ku, Kyoto, Japan. |

| 2004年 | FlexInspector is released at the Image Sensing Expo. |

| 2007年 | Obtained A-rank certification from the Kyoto City Venture Business Connoisseur Committee. |

| 2007年 | Moved to Kyoto City Foundation Support Factory. |

| 2011年 | Automatic appearance sensor FIS-100 is released. |

| 2014年 | FlexInspector-ROBO is released at the Kansai Mechanical Components & Materials Technology Expo. |

| 2019年 | Glamichanreleased. |

| 2022年 | Head office is moved to Kamitoba, Minami-ku, Tokyo. |