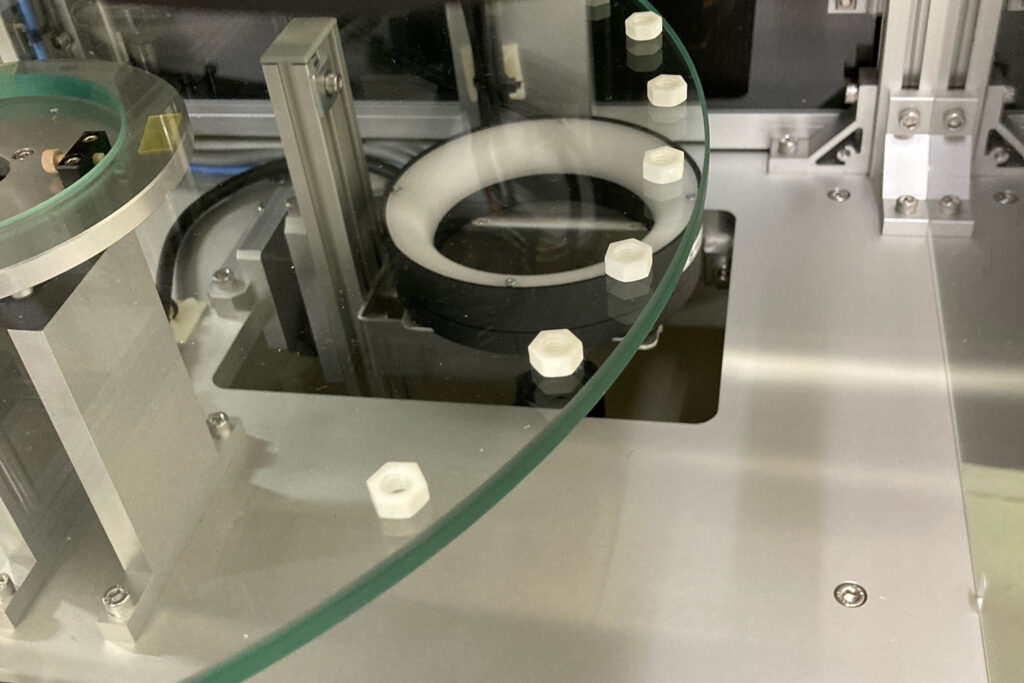

At manufacturing sites, various products and parts are made every day. Almost all of them are shipped after visual inspection. Our job is to automate these visual inspections using image processing technology, AI technology, robot technology, and other technologies to realize "profitable" visual inspections for users.

Can be used in the field.

No matter how great the detection capability of an inspection system, if it cannot be mastered on site, it will never reach its full potential.

Even those with no knowledge of image processing should be able to set up the system in a few minutes and sort out only the good products. This is a prerequisite for an inspection system that can withstand daily operation.

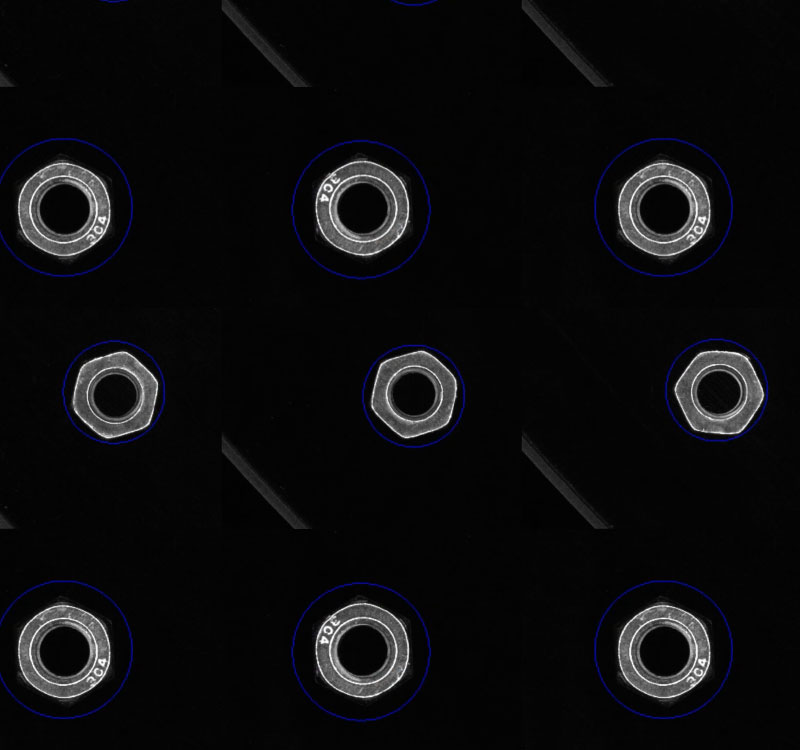

IF IT IS THE SAME AS A GOOD PRODUCT, IT IS JUDGED AS OK.

As a result of automatic inspection, defective products must not be mixed in with OK-judged products.

Generally, "all defects are defined by making full use of image processing, and if there is a defect, it is judged as NG," but our basic algorithm is "if it is the same as a good product, it is judged as OK. All defects are detected as differences from good products.

low cost

Visual inspection is a non-value-added job; therefore, a large investment should not be considered. 1,000+ units of experience has shown that the only ones that provide a return on investment are those that inspect from the end of in-line production, or those that have overwhelming speed.

In order to achieve a cost that is commensurate with the automation of visual inspection, we have spent over 10 years developing an inspection system that is not "object specific" but rather "capable of inspecting any specification" and "capable of inspecting anything. Therefore, additional development costs are rarely incurred.

For HAPPY Visual Inspection

In recent years, the need for automation of visual inspection has increased abnormally due to the problem of labor shortage. In addition, the development of AI technology is making it more accessible.

However, based on more than 20 years of experience, I can say with certainty that even with the development of AI technology, automation of visual inspection is difficult. It is difficult, expensive, slow, and even if it works, it will only bring us closer to people.... I don't feel that it will make the people involved happy.

WIN-win. We will make everyone involved in visual inspection happy by providing visual inspection equipment that will make users profitable.