We propose visual inspection systems that maximize return on investment according to the site environment and inspection object.

We develop not only the eye (image processing controller) but also the high-speed hand (handling) that maximizes its capability to provide a low-cost & high-performance system.

Image Processing Controller

FIS-200

Almost as good as good."Visual inspection sensors that inspect the Including previous versions of FIS-100 and FlexInspector, approximately 1,000 sets are currently in operation.

THE BASIC INSPECTION METHOD IS "REGISTER AN IMAGE OF A GOOD PRODUCT, AND IF IT IS THE SAME AS THE REGISTERED IMAGE, IT IS OK. ITEMS JUDGED AS OK BY THIS INSPECTION METHOD ARE GUARANTEED TO BE GOOD.

HOWEVER, THERE ARE ALWAYS FLUCTUATIONS IN GOOD PRODUCTS, AND THEY ARE NEVER EXACTLY THE SAME. THEREFORE, FIS-100 HAS A MECHANISM TO "STATISTICALLY" DETERMINE THE RANGE OF GOOD PRODUCTS BY SAMPLING A LARGE NUMBER OF GOOD PRODUCTS.

High-precision object is high precision, loose object is loose.

High-precision parts with high accuracy and loose parts with loose parts.

We realize such inspection.

COMPARED TO THE DEFECT-DEFINED APPROACH (DEFECTS ARE DEFINED USING IMAGE PROCESSING, AND IF DEFECTS ARE PRESENT, THEY ARE NG), THIS APPROACH HAS THE ADVANTAGES OF BEING OVERWHELMINGLY EASY TO SET UP AND RELIABLY DETECTABLE, REQUIRING ONLY GOOD PRODUCTS TO BE PREPARED, AND BEING HIGHLY VERSATILE.

COMPARED TO DEEP LEARNING-BASED AI, LESS ABILITY TO DEAL WITH VARIABILITY = HIGHER RELIABILITY (HARD-HEADED), SHORTER TRAINING TIME, EASIER OPERATION, AND LOWER COST. ABOVE ALL, IT HAS THE ADVANTAGE OF A PROVEN TRACK RECORD.

There is a reason why there are so many repeat users.

What does "almost the same as a good product" mean?

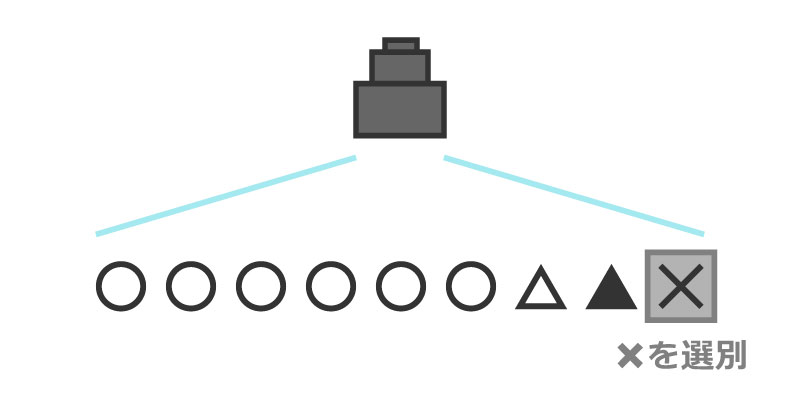

Conventional visual inspection

▼

In the case of conventional "× sorting" inspection, it is necessary to inspect almost all products in their entirety in order to sort out undetectable ▲. This is not a cost-effective method of automation.

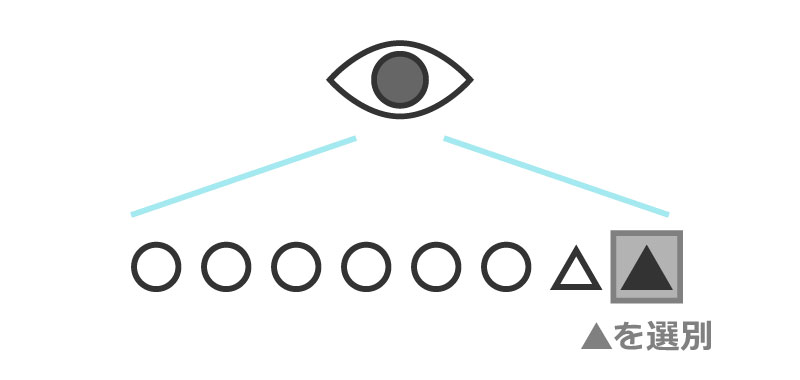

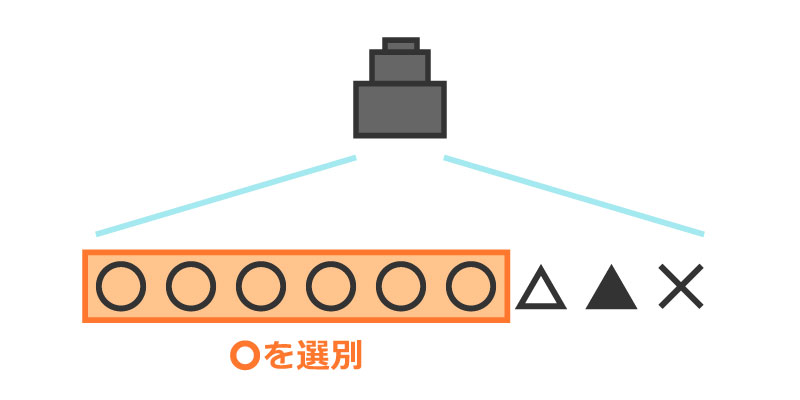

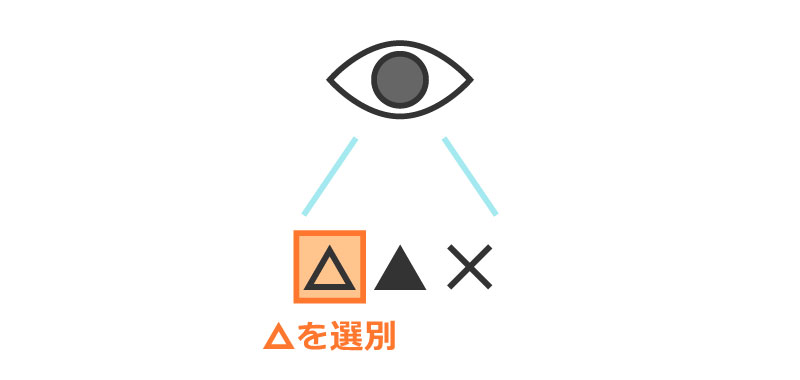

ovitVisual inspection of

▼

ovitThe visual inspection of the "0" is "0 sorting". Once good items are sorted by automatic inspection, only suspicious items are re-inspected.

FIS-200DL

AN AI FUNCTION-ENHANCED VERSION OF THE CONVENTIONAL FIS-200 VISUAL INSPECTION SENSOR, COMPLEMENTING THE WEAK POINTS OF THE FIS-200.

FIS-200 HAS A LOW TOLERANCE FOR GOOD FLUCTUATIONS AND "DEFECTS IN FLUCTUATIONS" ARE EITHER OVER-DETECTED OR UNDETECTABLE. AI (DEEP LEARNING) IS USED TO PROCESS FLUCTUATIONS MORE CORRECTLY.

ANOTHER WEAK POINT IS THAT "GOOD REGISTRATION IS NECESSARY. WE AIM TO REDUCE THE TIME AND EFFORT REQUIRED TO HANDLE MULTIPLE PRODUCTS AND SURFACES BY USING AI (DEEP LEARNING) TO MORE EASILY AND FLEXIBLY DEFINE DEFECTS.

CURRENTLY, SEVERAL FIS-100 USERS ARE CONSIDERING AND INTRODUCING THE SYSTEM AS AN "UPGRADE".

Comparison of Image Processing Controller Functions

| FIS-100 | FIS-200 | FIS-200DL | |

| feature | High reliability/short learning time and easy operation | High reliability/short learning time and easy operation | Flexible handling of good fluctuations |

| HALCON VERSION | Up to 12 | 18 or later | 18 or later |

| deep learning | nashi (Pyrus pyrifolia, esp. var. culta) | nashi (Pyrus pyrifolia, esp. var. culta) | ant |

hardware (esp. computer)

Glamichan

The only thing that can be "surpassed by humans" by automating visual inspection is inspection speed. High-speed "hands" are needed to increase inspection speed.

The " Glamichan" is a visual inspection system that can inspect the front and back of a product without flipping it over by transferring the object to be inspected on a glass disk. It aims for the fastest front-to-back inspection of at least one piece per second.

EASY MAINTENANCE, CAN BE USED FOR MULTIPLE PRODUCTS, AND CAN BE COMBINED WITH AI INSPECTION OF FIS-200.

This is how automation of visual inspection should be. Our answer.

ping-pong system

Hand-feeding approach to visual inspection. Audible notification if the product is good.

The eyes and brain are assisted by the machine, while the "hands," which are flexible and easily speeded up, are handled by a person. Since the object to be inspected is simply placed under the camera, the system can be operated by the elderly and physically challenged.

Inspection peeling of only one surface.

the rest

Automation cannot "replace people. It is meaningless unless it surpasses people.

We can only make money when the field is profitable.

Then we can do more interesting work.

Based on this belief, we are planning and developing interesting visual inspection equipment. Please feel free to contact us.

Flow of Introduction

- Email/Phone

- Please contact us by e-mail at info@ovit.co.jp or by phone at 075-203-7571.

- hearing

- We will interview you about the outline of the product to be inspected, the current manufacturing/inspection process, desired inspection tact, etc.

- preliminary experiments

- Please send 30 or more good samples and samples to be detected to us.

We will select lighting, lenses, etc. for evaluation of the demo equipment.

- Demo machine rental

- All the environments used in the preliminary experiments are available on loan for two weeks.

Please evaluate the operability, detection capability, and issues to be addressed when introducing the system on site.

- accepting an order

- Consulting on how to build a more effective visual inspection system.

Please consult us separately for special functions.

- introduction

- Vertical start-up can be expected if sufficient evaluation has been completed on the demonstration machine.

In actual products with small variations, detection capability tends to be more stable than in experiments.