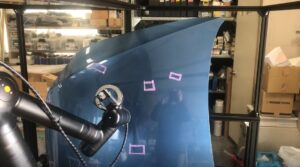

AI COMPARISON INSPECTION

WE ARE CURRENTLY IN THE PROCESS OF ADJUSTING AND IMPLEMENTING AN ACTUAL "AI COMPARISON INSPECTION" ON GLAMICHAN.

In the conventional comparative inspection, some fluctuation of good products can be tolerated, but the tolerance is small,

Although strict inspection is possible, it is not flexible, and the percentage of good products must be low.

AI COMPARATIVE INSPECTION ALLOWS "GOOD FLUCTUATION" TO BE HANDLED MORE FLEXIBLY THROUGH AI (DEEP LEARNING).

At the evaluation level, we had a feeling that it would be possible,

However, the cost increase of about 1.5 million yen was inevitable, and we had not yet introduced the product into the market.

IN THIS CASE, WE PROCEEDED IN A WAY THAT THERE IS " GLAMICHAN" FIRST, AND WE SHOULD KEEP AI SUPPORT IN MIND FOR "WHAT IF" SITUATIONS.

AS A RESULT, "AI COMPARISON INSPECTION, I'M GLAD I PREPARED!" IT IS.

I have handled a variety of objects, but this is the best ever in terms of detection capability and good quality rate.

The learning time is also acceptable, about 10 minutes.

CONSIDERING EVEN THE "GOOD PRODUCT RATE" AFTER INTRODUCTION, WE RECOMMEND "AI COMPARATIVE INSPECTION" WITH AN ADDITIONAL INVESTMENT OF 1.5 MILLION.

As a point of caution,

At present, the practical level is limited to "2 megapixel camera image x 4 planes" due to the limitation of PC capability.

AI Defect Detection" for multi-resolution imaging is also under evaluation.