Limitations of Human Sea Tactics

I thought to myself, "If we can get people to do visual inspections, there is no need to go to the trouble of automating them.

I myself thought that there was no need to go to the trouble of automating the process. I think the same was probably true at many manufacturing sites. In fact, I have seen sites where more than 30% of the employees are inspectors.

That is where the Corona disaster is this time.

When the coronas converge and production returns, what will happen to the processes that have been handled by manpower?

We will probably be forced to consider automating visual inspections.

A few points for those who are beginning to consider this.

- It is not easy to automate the process so that inspectors can be completely replaced.

- If the inspector is using his/her hands to change the posture of the object being inspected, the difficulty level is quite high. Conversely, if the inspector is not using his/her hands, it is easy.

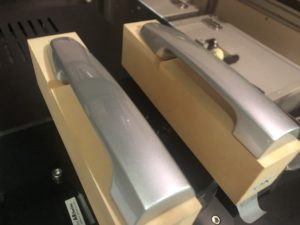

- The easiest and most reliable method is to inspect whether the shape of the object is the same as that of a good product if the shape of the object is stable. This is the only method that can be started up in a short period of time.

- Potential for deep learning for objects with unstable shapes. 70-80 point inspection is feasible, but beyond that, it is unknown.

- The most important factor is inspection speed, including object handling. If you cannot inspect faster than others, you will not get a return on investment. No one is happy with a job that does not give a return on investment.

- If we focus on detection capability, automation will not move forward.

We won't begin to talk about it until we get the coronas to converge first...